History

The “Package Boiler” evolved from the marine boiler which was first started in 1889. The U.S. Navy purchased its first coal-fired marine boiler from Babcock & Wilcox (B&W) in 1894. Since then, B&W boilers have been installed on more than 4,000 ships for the U.S. Navy and Merchant Marines. During WWII, B&W boilers were furnished to the Navy for all but two battleships.

With the onset of America’s economic recovery during World War II and the succeeding years, B&W responded with a new line of boiler to meet emerging customer demands. The FM (Factory-Made) Package boiler was introduced in 1949 in response to the needs of smaller to medium sized industrial plants that required a boiler that was compact and easy to install and operate. Since 1949, B&W has built over 4,300 Package boilers to service a wide variety of industries and applications.

Boiler Details

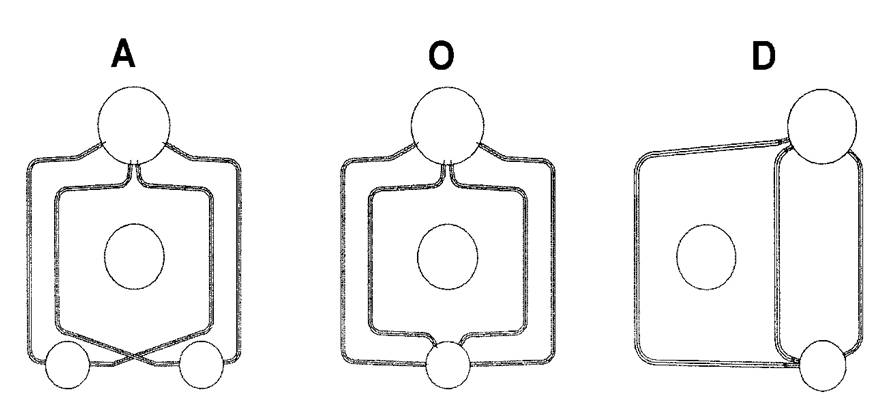

There are three main types of industrial watertube boilers:

- “D” Style - One steam drum and one lower drum, centered over each other with furnace offset to one side and one generating bank.

- “A” Style - One steam drum and two lower drums set in shape of “A”. Furnace is in the center of boiler with two generating banks.

- “O” Style - One steam drum and one lower drum, centered over each other with furnace in center and two generating banks.

The FM D-type water tube Package boiler is B&W’s most used Package boiler design. With the large furnace wall tube diameter and small 1” membrane between tubes, the FM boiler offers a large heat transfer area and water volume in the furnace section. This allows the FM boiler to be a very rugged and long-life boiler that fits most industrial boiler applications.

Babcock & Wilcox FM D-type boilers can be configured as left or right hand, and can be designed for a steam capacity of 10,000 to 300,000 lbs/hr, pressures from 250 to 1,250 psig, and a maximum temperature of 850F (for gas fired units). FM O-type boilers can be designed for a steam capacity of 6,000 to 300,000 lbs/hr, pressures from 250 to 1,250 psig, and a maximum temperature of 950F. Typical fuels include natural gas, fuel oil, refinery gas, coke oven gas, landfill gas, and digester gas.

Typical temperature turndown guarantee is 1:1. Greater temperature turndown requires the superheater to be oversized and terminal attemperation to be used. If required, the superheater materials can be changed from typical carbon steel which is good for 750°F to allow material such as SA213T22 tubes.