Nationwide Boiler is proud to be the exclusive representative for Hurst Boiler in California and the Greater Houston Area of Texas. This partnership provides customers with access to Hurst’s comprehensive range of equipment, including Hurst's well-known industrial packaged boilers, feedwater equipment, and custom-engineered solutions. Boiler equipment from Hurst is designed to meet the specific needs of a wide range of different industries.

Nationwide Boiler is proud to be the exclusive representative for Hurst Boiler in California and the Greater Houston Area of Texas. This partnership provides customers with access to Hurst’s comprehensive range of equipment, including Hurst's well-known industrial packaged boilers, feedwater equipment, and custom-engineered solutions. Boiler equipment from Hurst is designed to meet the specific needs of a wide range of different industries.

Founded in 1967, Hurst Boiler & Welding Co., Inc. is a family-owned business known for its high-quality, efficient, and reliable boilers. With over five decades of innovation, Hurst has become a trusted name globally offering a wide range of steam and hot water boilers, integrated systems, and ancillary equipment. The partnership between Nationwide Boiler and Hurst Boiler combines our shared commitment to excellence and innovation. By aligning our values, we ensure that our customers receive top-tier, reliable solutions backed by decades of expertise and cutting-edge technology.

As an exclusive representative for Hurst Boiler, we have the following packaged firetube boilers now in production. Your choice low or ultra-low NOx burner will be installed prior to shipment.

Nationwide Boiler's Package Firetube Boilers | |||

|---|---|---|---|

| 150 hp | 250 psig | 3-Pass Scotch Marine | ULN 2.5 ppm w/ Optional 30 ppm |

| 200 hp | 250 psig | 3-Pass Scotch Marine | ULN 2.5 ppm w/ Optional 30 ppm |

| 250 hp | 250 psig | 3-Pass Scotch Marine | ULN 2.5 ppm w/ Optional 30 ppm |

| 350 hp | 250 psig | 3-Pass Scotch Marine | ULN 2.5 ppm w/ Optional 30 ppm |

| 500 hp | 250 psig | 3-Pass Scotch Marine | ULN 2.5 ppm w/ Optional 30 ppm |

| 800 hp | 250 psig | Semi Wet-Back Package | Low NOx 30 ppm Option |

| 1000 hp | 250 psig | Semi Wet-Back Package | Low NOx 30 ppm Option |

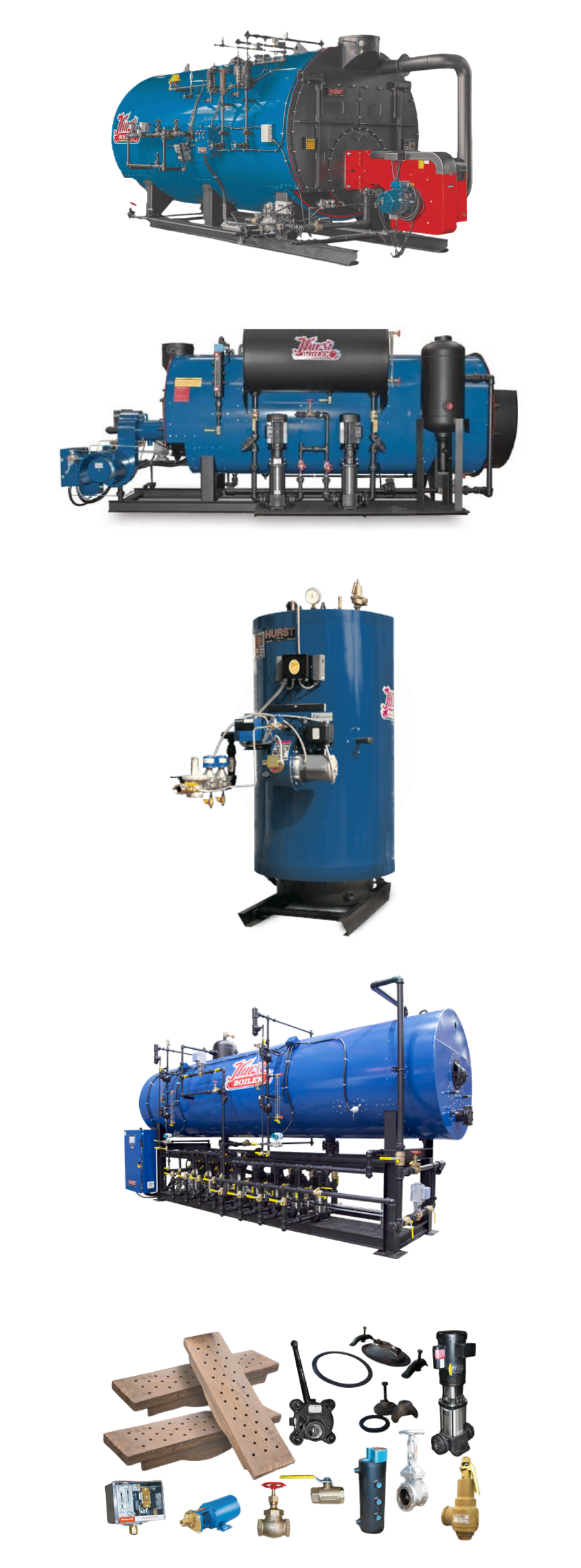

Scotch Marine Firetube Boilers

Available in two-pass, three-pass, and four-pass designs, Hurst’s Scotch Marine Firetube boilers can be built for both steam and hot water applications. Additionally, end-users can choose a wetback or dryback design with the main difference being the rear wall design. In a wetback, or waterback boiler, the rear wall is surrounded by water as opposed to being lined with refractory, like the dryback design. The capacities for Hurst Scotch Marine firetube boilers range from 15 to 800 HP with pressure ratings up to 300 psig.

Skid Package Systems

Hurst Boiler’s skid packaged systems are customizable packages with "Factory Matched" auxiliary equipment to minimize footprint and shipping costs. Hurst’s boilers are attached on steel skids and come with feedwater tanks, water softeners, and water treatment systems. Each transportable package is easy to install and available in standard or custom configurations, with options for automatic controls, monitoring devices, and all necessary fittings and wiring.

Vertical Boilers

Designed to maximize space efficiently while delivering exceptional performance, the Vertical Boiler features a compact design that ensures high efficiency, reduces fuel consumption, eliminates tubes, provides easy access to controls, and operates fully automatically.

The 47.5 HP Hurst Series 4VT boilers are a 4-pass vertical tubeless design that is pre-certified to meet the SCAQMD Rule 1146.2 requirement of sub 20 ppm NOx on natural gas. The Series 4VT boilers meet Cal Code, IRI, and Factory Mutual Codes, and are also UL and CSD-1 approved.

Boiler Auxiliary Equipment

Hurst Boiler also offers a wide range of auxiliary equipment to enhance the performance and efficiency of your boiler system. This comprehensive selection includes feedwater systems, blowdown separators, super heaters, surge tanks, and more, all engineered to integrate seamlessly with your operations.

Hurst Boiler Parts

High quality parts are available to support and enhance your boiler system, including burners, controls, valves, pumps, and more, all crafted for reliability and efficiency. Fast shipping is guaranteed to ensure timely delivery and minimize any disruption to your operation.