Steam tables are a valuable tool in the field of thermodynamics and are used in various engineering applications, including sizing a boiler system. Steam tables provide a comprehensive set of data and information about the properties of water and steam at different temperatures and pressures. When sizing a boiler system, steam tables are used for several purposes:

Steam tables are a valuable tool in the field of thermodynamics and are used in various engineering applications, including sizing a boiler system. Steam tables provide a comprehensive set of data and information about the properties of water and steam at different temperatures and pressures. When sizing a boiler system, steam tables are used for several purposes:

-

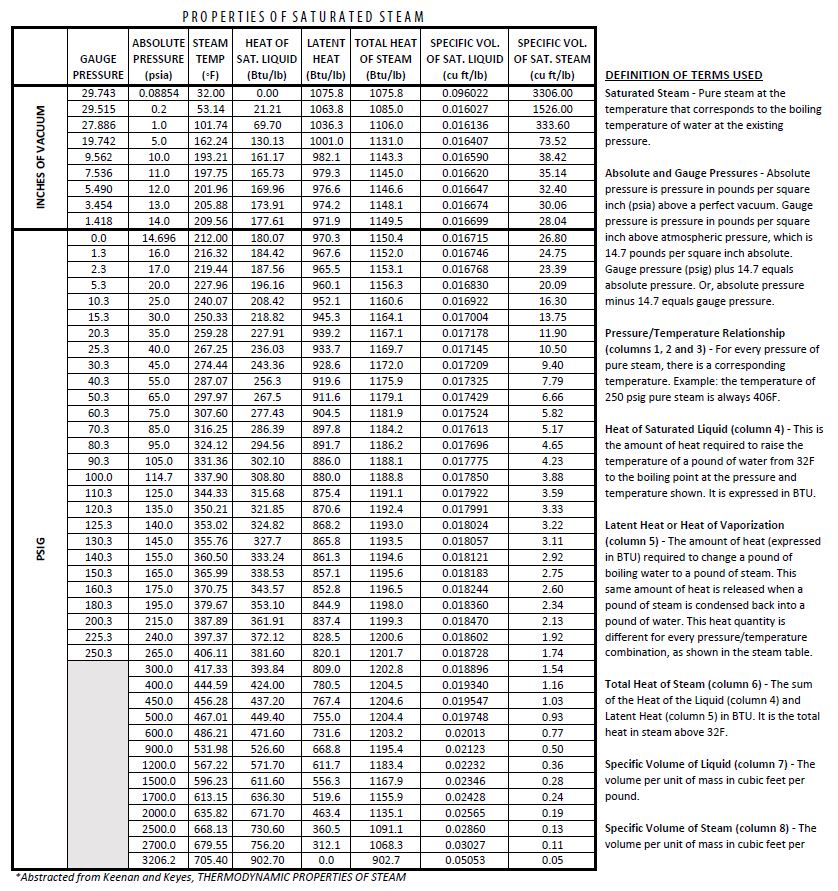

Determining Steam Properties: Steam tables provide critical information about the properties of steam, such as specific volume, enthalpy, entropy, and quality (whether the steam is saturated or superheated). Engineers use this data to understand how steam behaves at different conditions, which is essential for designing a boiler system that can meet specific process requirements.

-

Calculating Heat Transfer: In a boiler system, heat is transferred to water to generate steam. Steam tables help engineers calculate the amount of heat needed to raise the temperature of water to its boiling point and then to produce saturated steam or superheated steam. This information is crucial for sizing the boiler and selecting the appropriate heating elements.

-

Determining Steam Flow Rates: Steam tables are used to calculate the mass flow rate of steam required for a particular process. Engineers can use these tables to find the specific volume of steam and then apply it to the desired steam output to determine the necessary flow rate.

-

Pressure and Temperature Considerations: Steam tables help our engineers understand the relationship between pressure and temperature in a steam system. This information is vital for selecting appropriate safety valves, controlling the system's pressure, and ensuring that the boiler operates within safe limits.

-

Efficiency and Performance Analysis: Our engineers use steam tables to evaluate the efficiency and performance of a boiler system. By comparing the properties of the steam produced by the boiler to the requirements of the process, they can optimize the system for energy efficiency and reliability.

-

Sizing Steam Distribution and Condensate Return Systems: Steam tables are not only useful for sizing the boiler itself but also for designing the steam distribution and condensate return systems. Our engineers use steam properties to determine pipe sizes, insulation requirements, and other components necessary for efficient steam distribution.

Finally, you canutilize the steam table to assist with computing the amount of steam which will be condensed by any heating unit of known BTU output. Conversely, you can determine the BTU output if the steam condensing rate is known.