In 2005, a leading pharmaceutical company in California installed a new 1,000 hp package boiler with an ultra-low NOx burner and control system to meet current AQMD NOx emission levels of 9 ppm. The new boiler was installed the next year, but was unable to reach the maximum steam capacity due to an unreliable burner and the problems it experienced with maintaining low NOx operations. Excessive boiler vibrations, flame failures, and dangerous flame pulsations caused major reliability issues the customer wanted to address, in addition to meeting future NOx emission limits of 5 ppm and low carbon footprint.

In 2005, a leading pharmaceutical company in California installed a new 1,000 hp package boiler with an ultra-low NOx burner and control system to meet current AQMD NOx emission levels of 9 ppm. The new boiler was installed the next year, but was unable to reach the maximum steam capacity due to an unreliable burner and the problems it experienced with maintaining low NOx operations. Excessive boiler vibrations, flame failures, and dangerous flame pulsations caused major reliability issues the customer wanted to address, in addition to meeting future NOx emission limits of 5 ppm and low carbon footprint.

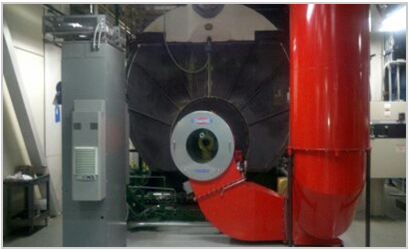

One Source Engineering was commissioned to conduct a steam reliability study to determine a more reliable and safe solution. The study concluded that replacing the burner with a more reliable, standard low NOx burner and offering a Selective Catalytic Reduction (SCR) system was the best solution. A new Limpsfield Combustion Engineering Ltd. burner and CataStak™ SCR system were chosen by One Source Engineering to meet the customer specific requirements. This included high quality equipment, efficient and reliable operation, and well-proven technology and experience.

One Source Engineering provided Autoflame controls and a standard Limpsfield burner, while Nationwide Boiler supplied the CataStak™ SCR equipment. The new equipment immediately achieved significant efficiency gains (reduced FD fan motor horsepower and lower excess air) and better operational performance (high turndown, increased flame stability, and flame retention). The CataStak™ SCR system reliably reduced NOx emissions from sub-30 ppm and was tested at 1 ppm NOx throughout the firing range. For the first time ever, the boiler was able to achieve maximum steam capacity with outstanding burner and emission performance.

The installation was a great success and both the Limpsfield burner and CataStak™ SCR system have been operating without the issues or problems experienced before the upgrade. The system operates at high turn down, low excess air levels, and ultra-low NOx performance, providing the customer with hassle-free operations and efficient performance.

After completion of this successfull project, the customer chose to retrofit another boiler on-site with Nationwide Boiler’s CataStak™ SCR System to provide ultra-low NOx emissions and confidence in their operations

![]() Download this CataStak SCR Project PDF

Download this CataStak SCR Project PDF

| CUSTOMER PROFILE | EQUIPMENT SUPPLIED |

|---|---|

| Major pharmaceutical company | 5 ppm NOx CataStak™ selective catalytic reduction system |

| United States: California | Low excess air and low NOx Limpsfield Combustion Engineering burner |

|

Ammonia delivery system with Nationwide Boiler’s NOx reduction control system |